Global experience, strong brand reputation, and comprehensive support for all customer needs

ISO9001 quality system certification, CE certification, and patent software copyright support

30 years experience, advanced technology, highly customized solutions, efficient and high-quality delivery

Five-star after-sales service, 24/7 support, customer-first approach, and fast response

Huludao Boyu Petroleum Machinery Co., Ltd.

Huludao Boyu Petroleum Machinery Co., Ltd. (Boyu Petro), established in 1996, is located in the Dayushan Pump Industry Park, Lianshan District, Huludao City, Liaoning Province, China. The company spans a total area of 20,000 square meters, with a building area of 9,000 square meters..

With 30 years of expertise, we specialize in developing and manufacturing equipment for oil tubing, casing, drill pipes, sucker rods, down-hole tools, as well as steel pipe testing and support. We take pride in our highly skilled technical team, stringent management systems, state-of-the-art processing equipment, and comprehensive testing capabilities. Our commitment to quality is reflected in our robust quality management system. In 2001, we achieved ISO9001 certification, and we have since obtained certifications for ISO14001 environmental management and ISO45001 occupational health and safety management, underscoring our dedication to excellence and sustainability.

Read MorePRODUCTS

Covering a wide range of pipe diameters and tool sizes, we support customized requirements. We provide a full-cycle equipment delivery solution, from R&D and design to machining, component assembly, factory acceptance testing (FAT), and on-site installation and commissioning.

Our product and service offer

Our solutions and systems are fully customized to meet our clients' specific needs, leveraging the latest available technology. We strictly adhere to the latest environmental developments and regulations to deliver high-value, sustainable products. Additionally, we offer comprehensive long-term support, including post-warranty service, with on-site consulting and technical assistance to ensure optimal performance.

-

Oil Casing and Tubing Production Line

-

Disassembly and Assembly of Downhole Tools

-

Hydrostatic Testing of Steel Pipes

-

Oil Casing and Tubing Repair Line

-

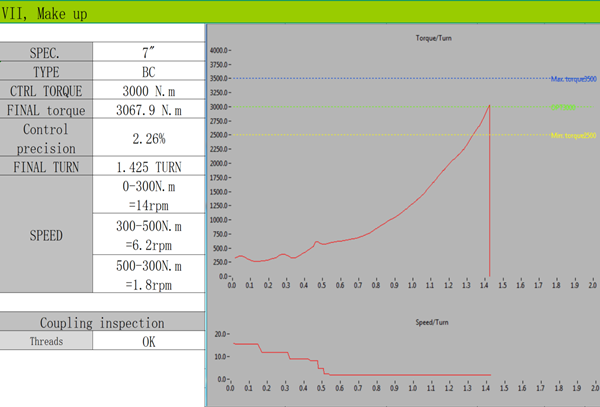

Torque Calibration Service

-

CNC System Upgrade and Reconstruction